Welcome to Changzhou Shiding Machinery Co.,Ltd.

Tel:+86-13506122422/13506122422 E-mail:cnyuanwei@163.comWelcome to Changzhou Shiding Machinery Co.,Ltd.

Tel:+86-13506122422/13506122422 E-mail:cnyuanwei@163.com

TEL:+86-13506122422

MOB:13506122422

E-mail:cnyuanwei@163.com

Add:No. 132 Guangyuan Road, Zouqu Town, Zhonglou District, Changzhou, Jiangsu, China

Description

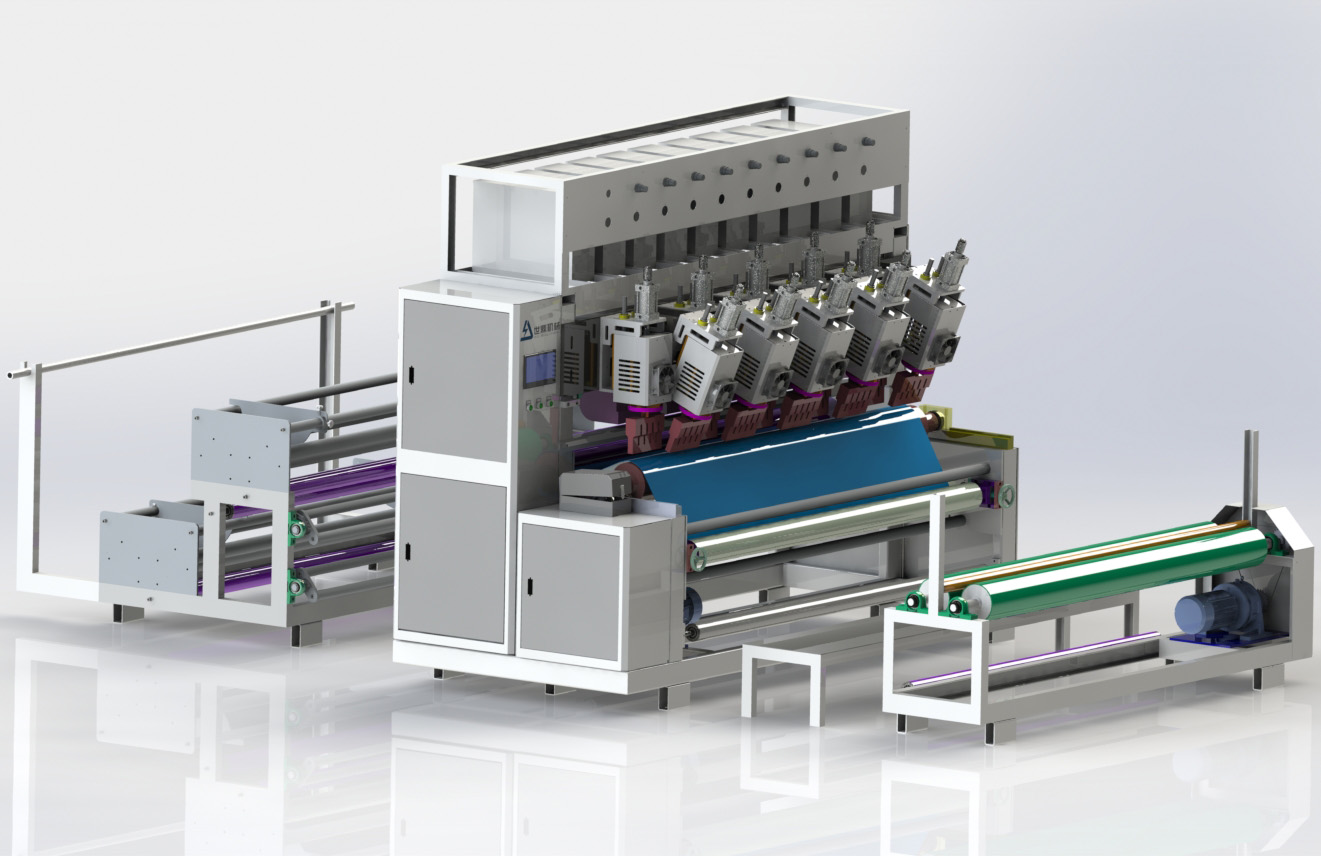

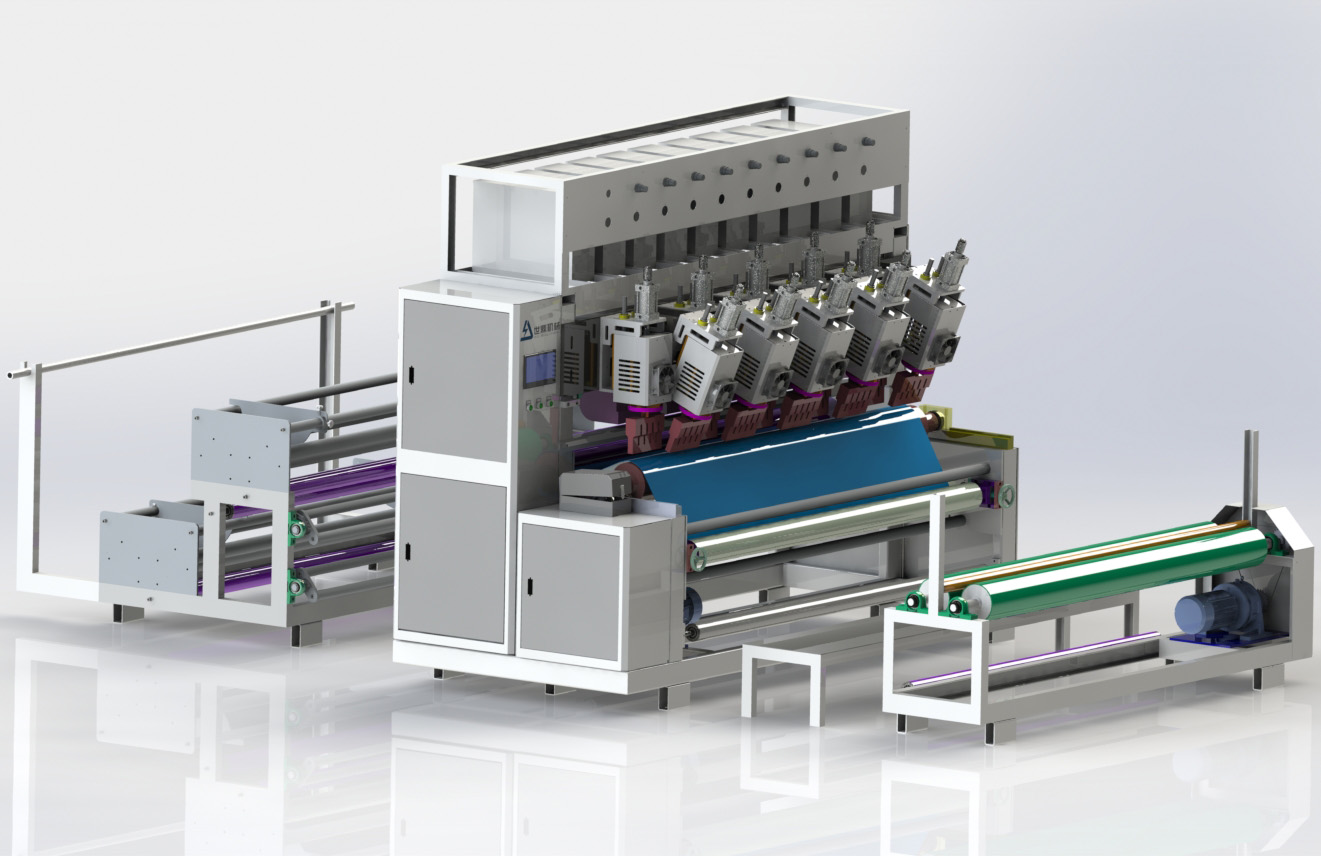

1. Ultrasonic quilting embossing machine utilizes ultrasound technology to complete no-needle, no-thread quilting operations. It can bond and emboss laminations of various chemical fiber fabrics, non-woven fabrics, gush glue cotton, and artificial leather.

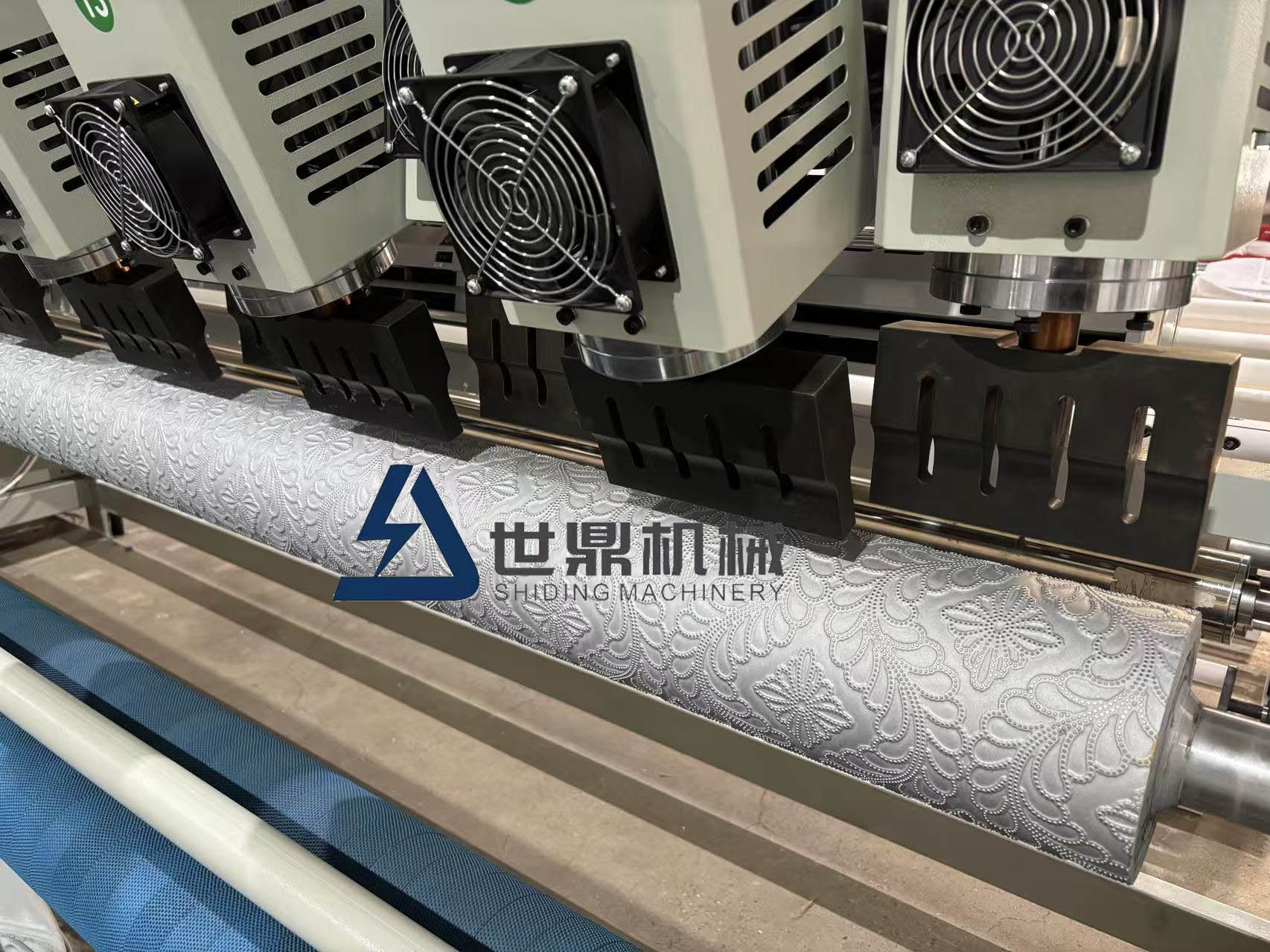

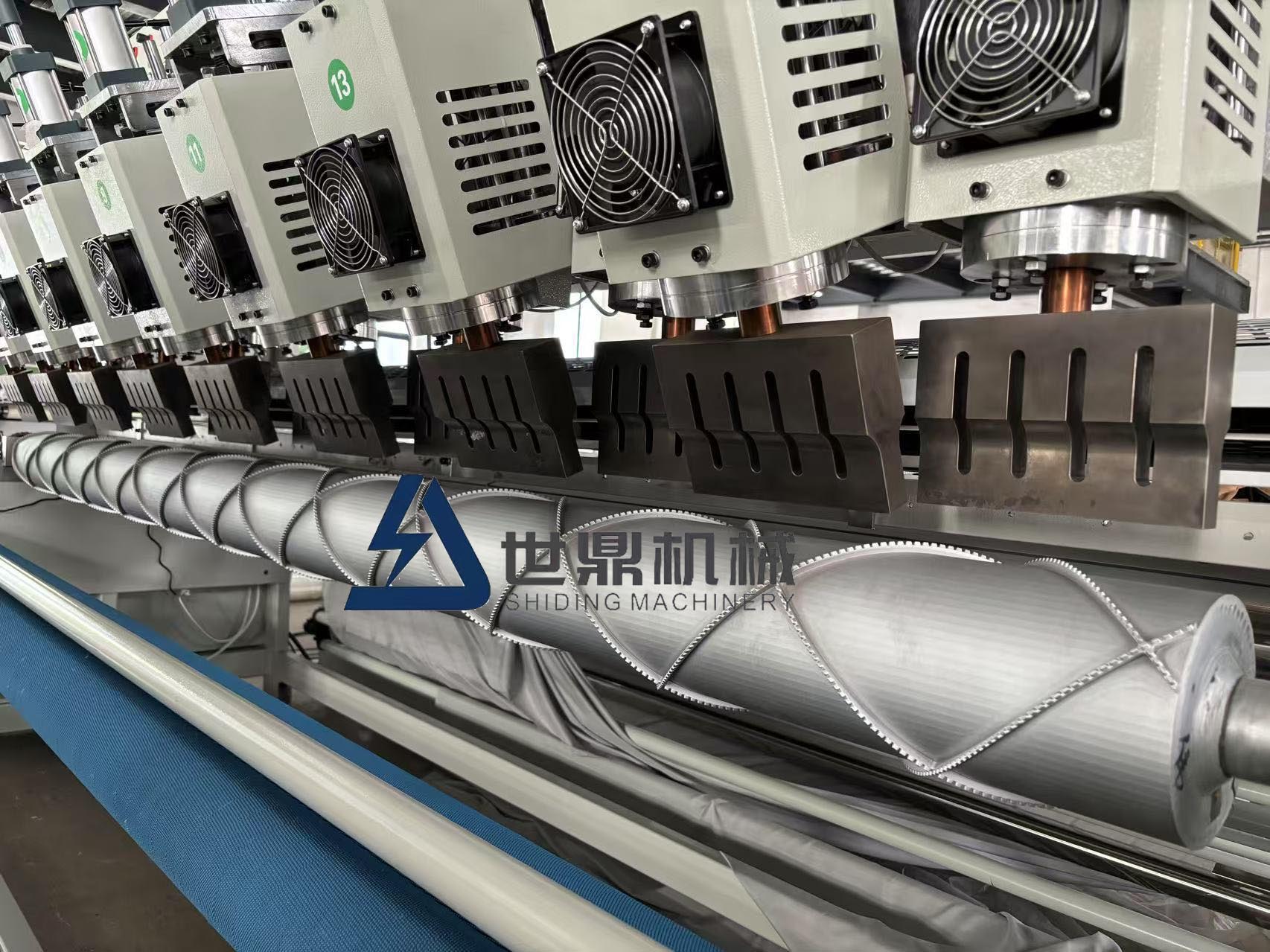

2. The machine is easy to operate and patters come out clear and beautiful. The fabric will not be easily deformed. The bonding is solid and without using needles, production efficiency is significantly increased.

3. According to customer demands, the pattern roller can also be freely replaced, allowing for different patterns with various effects to be pressed. It is an ideal equipment for the production of bedcovers, bedspreads, pillowcases, quilt covers, quilt, mattress, sofas, car mats, garments and bags, etc.

Samples

Parameters

Model | Power supply | Effective width | Dimensions | Net weight |

SD-1000-Q | 7KW 380V 3 phase (220V) | 1000mm | 5x1.5x1.8m | 1000KG |

| 7KW 380V 3 phase (220V) | 1500mm | 5x2x1.8m | 1500KG | |

8KW 380V 3 phase (220V) | 1800mm | 5x2.3x1.8m | 1800KG | |

8KW 380V 3 phase (220V | 2300mm | 5x2.8x1.8m | 2300KG | |

9KW 380V 3 phase (220V) | 2600mm | 5x3.1x1.8m | 2600KG | |

9KW 380V 3 phase (220V) | 2800mm | 5x3.3x1.8m | 2800KG | |

9KW 380V 3 phase (220V) | 3000mm | 5x3.5x1.8m | 3000KG |

Features

1. Equipped with pneumatic horns lifting system, which can quickly correct its levelness and pressure stability.

2. Avoid the trouble of needles and threads of traditional sewing through the use of unique no-thread quilting technique.

3. The quilting width varies from the minimum value to 3000mm, and any pattern can be created simply by replacing the pattern roller.

4. Using an imported ultrasonic transducer with powerful sound wave, the quilting effect completed in a high level of quality.

6. Simple operation, high quilting strength, high production efficiency.

7- Structure of machine 1) Fabric feeding rack 2) Pattern press compound machine 3) Ultrasonic control cabinet 4) End fabric rolling device.