Basic components

1. New type PC intellectual ultrasonic generator;

2. 18KHz ultrasonic transducer unit;

3. Single motor speed adjustment system;

4. Manual roller lifting system;

5. Super large head system, extra-width pattern roller to process larger diameter

Characteristics

1. Built-in PC chips, multi-circuit ultrasonic protection system to make the machine run safely;

2. Strong ultrasonic power with three adjustable gears (maximum, medium and minimum), meets the welding requirements of different materials and thicknesses;

3. The performance of the machine reaches international level with automatic frequency tracking system and ultrasonic soft-starting technology;

4. Installing roller with larger diameter to manufacture special lace and craft flowers, etc.

Functions

1. Trimming: Straight or curvilinear edge cutting and edge treatment for melting, so smooth, no rough edges;

2. Sealing: Two or more layers of fabric stitched together without thread replacing the sewing needles, good welding strength;

3. Hole making: Cut out the various patterns of holes, and treatment of side melting;

4. Slitting: Single or more cutting of the material at the same time, and treatment of side melting without burr;

5. Forming: Simultaneous cutting, sealing and embossing to make production in one time.

Technical parameter

Source power | 220V±5V or 110V avaliable |

ULT. power | 2000-2500W |

Output frequency | 18KHZ |

Working speed | 0-20m/min |

Roller size | Width: 0-190mm; Diameter: Ø50-Ø80mm |

Dimension(L*W*H) | 1200*600*1200mm |

Net weight | 120KG |

Applications

Apply to lace clothing, ribbon, decoration products, handkerchief, tablecloth, curtain, bedspread, pillowcase, quilt cover, non-woven fabric products and so on.

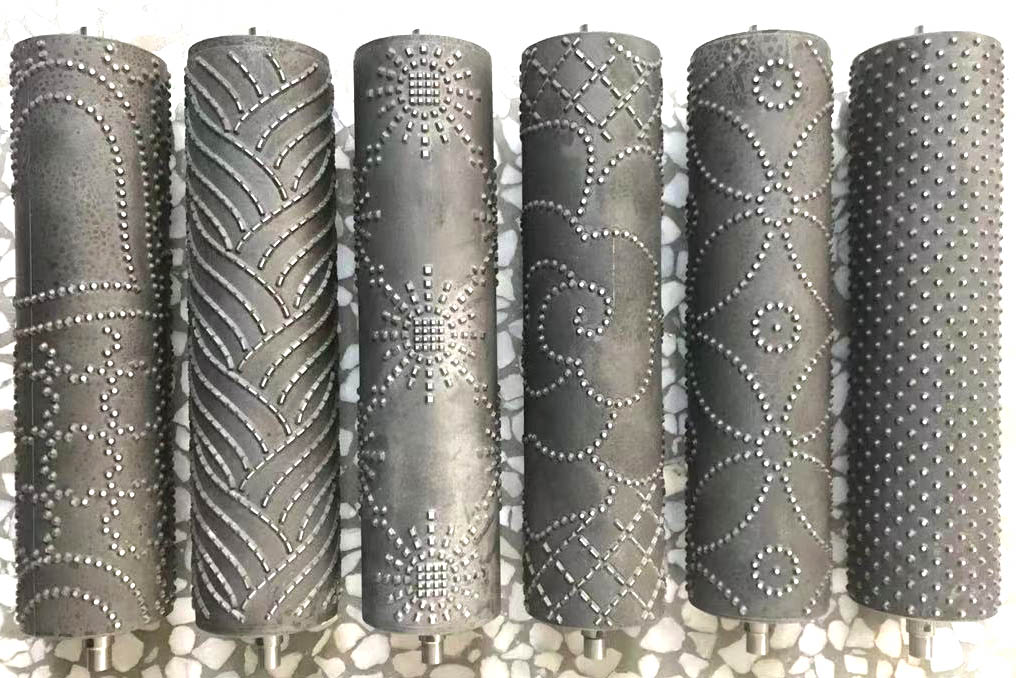

Fabric sample& Rollers